MOTORIZED DRIVE CASTER® SOLUTIONS: TAKING CONTROL OF MOBILITY

Answering The Most Asked DRIVE CASTER® Questions

When cart loads exceed 2,500 pounds, they become difficult to move manually. Initial push force requirements, tight spaces, overexertion injuries, and other problems can keep a cart from being utilized. In these instances, using a DRIVE CASTER® or another motorized DRIVE CASTER® solution can solve these issues effectively and affordably.

The Motorized DRIVE CASTER®, are powered casters that integrate an electric motor with an industrial caster to create a single unit that’s added to carts, racks, or anything that rolls on casters. This helps employees effortlessly move thousands of pounds of equipment with little to no exertion required. To determine the best setup for your application, you first want to know the capacity of your casters and how much load you are moving.

WHAT’S THE DIFFERENCE BETWEEN WEIGHT CAPACITY AND DRIVE CAPACITY?

Determining the difference between weight capacity and drive capacity is an often-asked question. Weight capacity is how much weight that individual caster is rated to carry before a risk of failure. Different casters have different load ratings, an essential factor to consider regardless of whether the cart is moved manually or by a motorized caster. In general, caster weight classifications look like this:

- Medium Duty – Designed for capacities up to 1500 pounds.

- Heavy Duty – Designed for capacities up to 5,000 pounds.

- Extra Heavy Duty – Designed for capacities up to 20,000 pounds.

- Super Heavy Duty – Designed for capacities up to 50,000 pounds.

Drive capacity is how much total weight (the cart plus the load weight) a single Powered Caster Drive can move in a straight line on a smooth surface. If you require turning on uneven, cracked, or other imperfect surfaces, you have a couple of options. Either reduce the drive force by 50% or add a second DRIVE CASTER® to achieve the same drive capacity.

You can also add the patented Caster ShoX absorption unit that allows for about a half-inch of flexibility. This helps ensure drive engagement on uneven flooring and allows for some flexibility without excessive vibration.

HOW MANY DRIVE CASTER® CAN I PUT ON ONE CART?

DRIVE CASTER® motors support Rack and Pinion steering and tank-style steering. The tank-style configuration utilizes two Motorized DRIVE CASTER®. One motor moves in reverse while the other DRIVE CASTER® moves forward. Rack and Pinion would handle similarly to a car, requiring a larger turning radius.

If the weight of the load requires more DRIVE CASTER®, you can easily configure a cart using all DRIVE CASTER®.

We suggest using rigid casters as the first set of DRIVE CASTER® in these circumstances. Swivel DRIVE CASTER® can be added for additional power. Keep in mind that the battery size should increase with additional DRIVE CASTER®.

WHAT A DRIVE CASTER® INCLUDE?

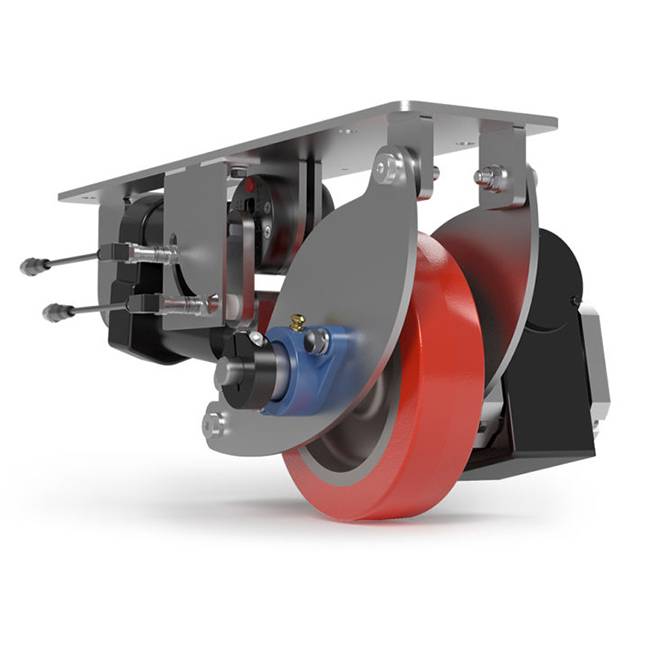

The DRIVE CASTER® includes the drive wheel, caster rigs, and a motor.

The motor has wiring for connection to a battery and a logic controller (not included). A DRIVE CASTER® will require the integration of additional components to be functional. If you require assistance with integration, Caster Concepts can create a complete solution for your needs.

The DRIVE CASTER® is available with numerous wheel and top plate offerings. Wheels are polyurethane on cast iron; many other polyurethane formulations are available. Your application and environment determine the proper polyurethane. Wheel sizes are 5″, 6″, 8″, and 10″ diameters with a 2″ width.

View all of our motorized caster products, including the HaloDrive Pod, and conversion casters.

As we continue to innovate and push the boundaries of mobility technology, Conceptual Innovations remains at the forefront of delivering Motorized DRIVE CASTER® Solutions that empower businesses to move forward with confidence, efficiency, and precision.