Transform Outdated Machines with Our Equipment Retrofitting Experts

Transform Outdated Machines with Our Equipment Retrofitting Experts

Don’t Toss It, Transform It.

Why settle for underperforming equipment when you can elevate it beyond expectations?

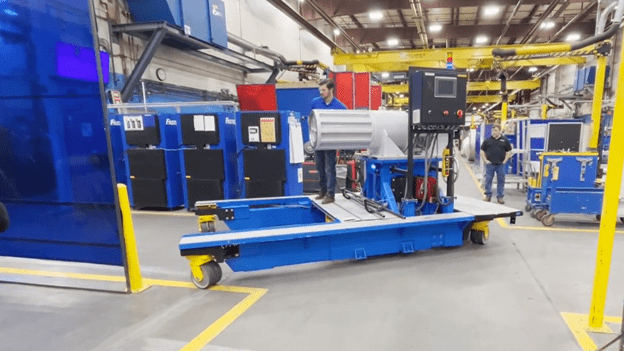

Conceptual Innovations specializes in bringing tired, outdated machines back to life, supercharged, optimized, and ready to outperform modern manufacturing standards.

Our retrofitting expertise does more than restore functionality; it unlocks untapped potential, enhancing performance and extending the lifespan of your assets.

Forget the debate between air casters, forklifts, or cranes. The real question is: Are you ready to push your business to new heights? Retrofits deliver unmatched efficiency and power while keeping your bottom line intact. Let us show you how:

ADVANTAGES OF DRIVE SYSTEMS RETROFITTING COMPARED TO OTHER CONVENTIONAL METHODS.

| Aspect | Retrofitting | Air Casters | Forklifts | Overhead Cranes |

|---|---|---|---|---|

| Cost Efficiency | – Reduces capital expenditures by reusing existing chassis. | – Requires specialized flooring, which can get expensive. | – High upfront and operational costs. | – Expensive to install and operate. |

| Operational Disruption | – Minimal impact on operations | – Limited controllability | – Significant space to maneuver | – Limited area of operation |

| Ease of Use | No additional operator training is required. | Limited by floor quality | -Confined space limits movement | – Requires licensed operators and complex setup. |

Retrofitting helps you cut costs, not corners.

1. Reduce Capital Expenditures/Expand Capacity

- Extend the useful life of existing equipment for greater savings, especially if it has already been depreciated and paid for.

- Add advanced features such as lifting tables, tilting cradles, motorized movement, and safety stops to expand existing functionality — the most cost-effective way to increase productivity.

- Add or Integrate into existing automation, adding sensorization that will improve productivity and safety

2. Shorter Lead Times

- Since the base cart is already available, retrofitting ensures quicker project completion while maintaining your facility’s productivity.

3. Minimal Impact on Operations

- By limiting the time equipment is out of service, retrofitting reduces disruptions to your production processes.

4. Lower Startup and Integration Costs

- Incremental automation improvements are budget-friendly and come with fewer startup, commissioning, and integration challenges.

- Retrofitted equipment integrates seamlessly with your current controls, practices, and workflows.

- No retraining of operators is needed.

5. Engineering Expertise

For decades, we have been a trusted partner to clients in industries ranging from aerospace and automotive to medical and marine. Our engineering expertise encompasses electrical, hydraulic, and mechanical systems, allowing us to:

- Integrate electric drive systems into equipment under development or retrofit existing platforms.

- Customize base models with features and functionalities tailored to your application.

- Engineer fully custom systems designed specifically for your unique needs

Retrofitting MRI Magnet Cart for Phillips Healthcare

For years, Philips Healthcare relied on air bearing carts to transport 12,000 lb. MRI magnets through its production facility. The technology—essentially riding on a cushion of air—offered smooth, resistance-free motion in theory. But in reality, moving the cart was often challenging.

Any debris or even small floor cracks would cause the airbag to deflate. Once that happened, it was like trying to slide a car across the floor. Attempts to improve the system, like upgrading wheels or contacting mobility providers, fell flat. Most solutions didn’t fit the existing cart design, and companies that Jake contacted for support weren’t willing to offer a solution if it didn’t come off the shelf.

The Conceptual Innovations team collaborated closely with Jake and his team to understand their needs and deliver a custom-engineered solution that precisely fit their operations, workflows, and space constraints. In this case, rather than forcing Philips to redesign their cart or process, Conceptual Innovations built around Philips’ existing infrastructure—a key difference from every other vendor.

Click to read the Phillips Case Study

Click to watch the Interview

Retrofit for Maximum Productivity and Minimal Disruption.

When deciding between a costly large-scale capital project and a more strategic incremental improvement, retrofitting existing material handling platforms can be the perfect solution without the price tag.

Conceptual Innovations can bring new life to low-performing equipment that will exceed manufacturing performance specifications. Don’t cart away tired machines that can’t keep up. Revitalize them by utilizing our expertise for the most cost-effective way to increase productivity.

Contact a Conceptual Innovations solutions specialist to improve your facility’s capacity and functionality while minimizing costs, downtime, and disruption.