From Air Bearing Carts to Absolute Handling Control: Retrofitting a MRI Magnet Cart Transport.

Client: Philips Healthcare

Solution Provider: Conceptual Innovations

Project Lead: Jake Cetnar, Senior Mechanical Engineer & Program Manager

The Challenge: Moving a 12,000 lb. MRI Magnet Cart with Minimal Risk.

For years, Philips Healthcare relied on air bearing carts to transport 12,000 lb. MRI magnets through its production facility. The technology essentially riding on a cushion of air offered smooth, resistance-free motion in theory. But in reality, moving the cart was often challenging.

For years, Philips Healthcare relied on air bearing carts to transport 12,000 lb. MRI magnets through its production facility. The technology essentially riding on a cushion of air offered smooth, resistance-free motion in theory. But in reality, moving the cart was often challenging.

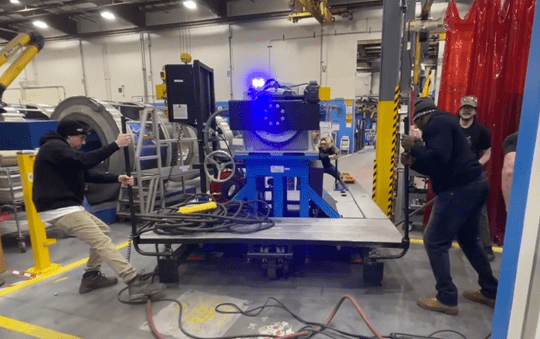

“Any debris or even small floor cracks would cause the air bag to deflate. Once that happened, you’re basically trying to slide a car across the floor,” said Jake Cetnar, Senior Mechanical Engineer and Program Manager at Philips. “You needed four to six people just to get it unstuck.”

That lack of reliability didn’t just slow down operations it introduced serious safety risks. Overexertion injuries were common. Worse, once the cart regained air and started floating again, it became hard to stop, posing pinch and collision hazards on the shop floor.

Attempts to improve the system, like upgrading wheels or contacting mobility providers, fell flat. Most solutions didn’t fit the existing cart design, and companies that Jake contacted for support weren’t willing to offer a solution if it didn’t come off the shelf.

Goodbye Airbags. Hello HaloDrive: A Retrofitted Solution Based on Existing Infrastructure.

Initially contacting Caster Concepts for a better drive wheel, Jake was introduced to Conceptual Innovations, the engineering division specializing in customized mobility. Skeptical but curious, Jake agreed to a site visit.

“I thought it was going to be another sales pitch. But once I saw the Conceptual Innovations flyer and learned about their HaloDrive™ system, I realized we might finally have a real solution.”

After flying to Michigan to test the system in person, Jake and his team quickly saw the value.

HaloDrive™ omnidirectional industrial electric carts safely transport the heaviest and largest loads, regardless of their shape, size, or other unique requirements. The patented HaloDrive™ System maneuvers easily through and around obstacles with omnidirectional maneuverability while providing extreme accuracy for alignment and positioning. These systems are a safer alternative to forklifts, overhead cranes, and other high-risk, difficult-to-operate, and space-consuming equipment and do not require a certified, highly skilled operator to use.

The Conceptual Innovations team collaborated closely with Jake and his team to understand their needs and deliver a custom-engineered solution that precisely fit their operations, workflows, and space constraints. In this case, rather than forcing Philips to redesign their cart or process, Conceptual Innovations built around Philips’ existing infrastructure a key difference from every other vendor.

The Impact: Safety, Efficiency, and Scalability.

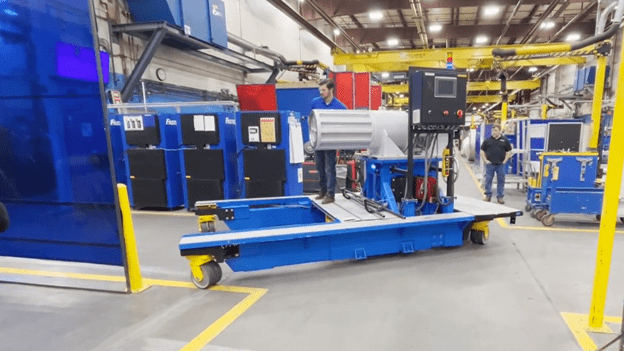

The final system featured two motor-powered, omnidirectional HaloDrive™ Pods that can be independently steered and driven, enabling unrestricted movement in any direction, at any angle. Four Twergo® Casters were also incorporated to minimize friction and scrubbing, allowing for smoother motion with less force. For battery-powered vehicles, less push force means longer battery runtime and reduced drive system stress while optimizing efficiency. This setup maintained the existing cart dimensions and weight specs.

“It now takes one person with a joystick and 30 seconds of training to move this massive cart with quarter-inch precision,” Jake said. “And we can stop it exactly where we want—safely.”

Following the success of the prototype, Philips retrofitted two more MRI carts and is seeking funding to convert more. This was due to the many benefits of retrofitting with a HaloDrive System, including:

Reduced Labor – Down from 4–6 operators to a single user.

Improved Safety – No more pushing, pulling, or runaway carts.

Increased Precision – Operators can now maneuver tight spaces with surgical accuracy.

Business ROI – Saved more than 60% compared to full equipment replacement.

And perhaps most importantly:

“This project was greenlit because it solved a major safety hazard. If sharing our story prevents even one injury at another company, it’s worth it.”

Why It Worked: Custom Engineering Meets Real-World Manufacturing.

Unlike other vendors, Conceptual Innovations didn’t try to sell something off the shelf. They worked side-by-side with Philips’ engineering team to deliver a tailored solution.

“We didn’t have to compromise,” Jake said. “Conceptual Innovations gave us a system that feels engineered for us, not at us.”

To learn how Conceptual Innovations can help you achieve a safer and more efficient operation, call 269.248.7637, or contact us to find out more about our automated material handling systems.