The Pros and Cons of Retrofitting Equipment

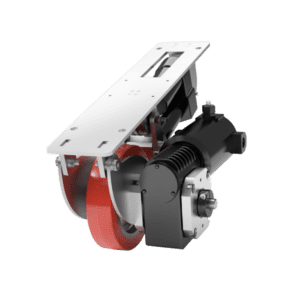

Aging is inevitable for all living things and inanimate objects: Equipment used in business operations will generally experience greater wear and tear as its volume of use increases. This is especially true for material handling equipment. Retrofitting traditional heavy-duty casters with motorized DRIVE CASTER® can give them a new lease on life, boosting productivity.

Material Handling Equipment Wear and Tear

Equipment used for transporting materials tends to experience high wear and tear and is at a higher risk of damage because of its constant movement.

These effects primarily impact the wheels used to move the equipment. For transport carts and Automated Guided Vehicles (AGV), casters take the brunt. Fortunately, replacing DRIVE CASTER® is relatively easy, and gives equipment new life.

In addition to replacing or upgrading to DRIVE CASTER®, retrofitting the equipment for new operations or challenges is an option.

A project we completed for NASA is an excellent example of this method. A risk was identified with the flooring in the facility: By retrofitting two large custom-built transport units to distribute the weight of the transports, the units were able to operate safely on the flooring.

Click to read the NASA case study.

The Benefits of Retrofitting Equipment

Retrofitting equipment has two main benefits:

- Reducing costs – Capital equipment and implementation costs.

- Saving time – Retrofits are often quicker and easier to implement, especially if the equipment is retrofitted during scheduled maintenance.

Other retrofitting advantages are:

- Waste reduction – Once the equipment is retired, it must be disposed of. There is no need to worry about where that old equipment will end up.

- Environmentally sustainable – Even if the equipment is recycled, it will most likely be melted down, producing smoke and other harmful gasses. Additionally, handles, fasteners, etc., cannot be recycled.

- Reduced risk of operator injury – Operators will not require training, nor will they need to adapt to new equipment.

Retrofitting Disadvantages

While retrofitting equipment has some valuable benefits, the disadvantages and potential risks cannot be ignored. These include:

- Functional failure due to the age or usage of the equipment.

- The sacrifice of certain features or functions due to limits on modifications.

- Modifications that may void the warranty.

- Difficulty finding replacement or maintenance parts.

These risks only apply to specific equipment and should be assessed case-by-case.

How to Decide if Retrofitting Equipment is the Right Solution

First, assess every piece of equipment being considered: check for any damage and structural integrity (if the equipment is at risk of failure, retrofitting should no longer be considered). Additionally, if the equipment is stable, consider the cost difference, which includes the price of new equipment vs. retrofitting equipment and the cost of downtime, training, implementation, etc.

How We Can Help

Conceptual Innovations engineering services can assess your application and equipment to determine the best action for your needs. Contact us to learn more.